Applications of Insulation Piercing Connectors in 5 Major Industries: Safer and More Durable Connections

Insulation piercing connectors (IPCs) are a revolutionary technology in the world of electrical connections. This often-overlooked electrical tool has revolutionized the way we connect wires in a range of applications, from the power grid to home electronics. The IPC is more than just a convenience; it’s a critical innovation that promotes safety, efficiency, and unprecedented connectivity across a variety of industries.

Utility Use of Grid-Insulation Piercing Connectors

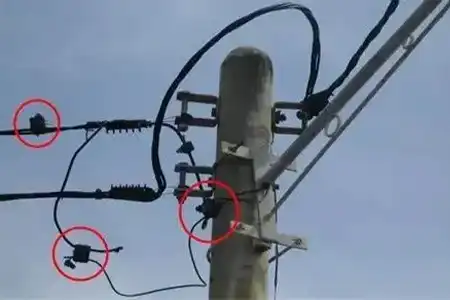

IPCs play a vital role in streamlining infrastructure in the vast utility sector where power distribution is critical. These connectors help connect overhead lines and underground cables, which are the arteries of the power grid, faster and safer.

Traditionally, utility workers would spend hours meticulously stripping insulation from wires before making connections. Now, with the advent of Insulation Piercing Connector, a simple twist-lock action pierces the insulation and provides a contact surface that ensures a reliable electrical connection. This not only saves time but also improves safety as it reduces the risk of electrical accidents.

In addition, IPCs play an important role in a variety of applications in the utility sector, from smart meter installation to street lighting maintenance. This versatility, coupled with their durability in harsh environmental conditions, makes them an indispensable asset for utility companies worldwide.

Electrical Distribution Systems

In the utility sector, Insulation Piercing Connectors play a crucial role in electrical distribution systems. These connectors are used to connect overhead and underground power lines, ensuring a stable and reliable power supply. The ability of IPCs to make connections without stripping the insulation significantly reduces installation time and labor costs. Moreover, IPCs provide a secure and durable connection that withstands environmental stressors such as moisture and temperature fluctuations, making them ideal for utility applications.

Smart Grid Integration

The integration of smart grids is another area where Insulation Piercing Connectors shine. Smart grids rely on a complex network of sensors and devices to monitor and manage the electrical grid in real-time. IPCs are used to connect these sensors and devices to the main grid, facilitating seamless communication and data transfer. The reliability and ease of installation of IPCs make them an excellent choice for smart grid applications, where maintaining uninterrupted power and data flow is critical.

Telecommunications Industry Adopts Insulation Piercing Technology

Communication is the lifeblood of modern society, and the telecom industry relies heavily on Insulation Piercing Connector for fast and stable connections of lines in telephony, data transmission, and broadcasting.

Telecom engineers have found that IPC provides a cost-effective and fast solution to the task of wiring, reducing labor time in the field. High-frequency signals require impeccable connectivity, and IPC provides just that, minimizing signal loss or interference.

From fiber optic installations to communication tower maintenance, IPCs have become an essential tool for telecom companies. Their ability to penetrate all types of insulation and ensure compatibility with the wide range of cables used in the industry has cemented their position as the technology of choice for secure and long-lasting connections.

Network Cabling

In the telecommunications industry, Insulation Piercing Connectors are widely used for network cabling. These connectors ensure stable and secure connections for data transmission, which is vital for maintaining the integrity of telecommunication networks. IPCs’ ability to pierce the insulation without damaging the conductors is crucial for high-quality signal transmission, making them a preferred choice for network cabling projects.

Fiber Optic Networks

Fiber optic networks, which are the backbone of modern telecommunications, also benefit from IPC technology. Insulation Piercing Connectors are used to connect optical fibers, ensuring efficient and reliable data transmission. The precision and reliability of IPCs make them ideal for managing the delicate and high-speed connections required in fiber optic networks.

Automotive engineering: Insulation piercing connectors in vehicle wiring systems

The automotive industry is marked by constant innovation, and Insulation Piercing Connector has found its place under the hood, contributing to the efficiency and reliability of vehicle wiring systems.

In modern vehicles, electronics play an ever-expanding role, from fuel management systems to on-board diagnostics. IPC technology offers automotive engineers a way to connect these systems without compromising the integrity of vehicle wiring.

Their non-destructive piercing action allows connections to be made without damaging the wire insulation, thus maintaining the original properties of the wire. Whether in volume production or aftermarket improvements, Insulation Piercing Connectors have proven to be an invaluable resource for the automotive industry to ensure consistent performance and energy management.

Vehicle Wiring Harnesses

The automotive industry relies heavily on IPCs for vehicle wiring harnesses. These harnesses are essential for connecting various electrical components within a vehicle, such as lights, sensors, and control units. Insulation Piercing Connectors provide reliable connections that can withstand the harsh conditions inside a vehicle, including vibrations, temperature changes, and exposure to moisture.

Electric Vehicles

With the rise of electric vehicles (EVs), Insulation Piercing Connectors have become even more critical. EVs require efficient and reliable electrical connections to ensure optimal performance and safety. IPCs are used to connect battery packs, charging systems, and other electrical components within EVs, ensuring efficient power transmission and reducing the risk of electrical failures.

Aerospace Applications: Ensuring Reliable Connections with Insulation Piercing Connectors

The aerospace industry has stringent standards and electrical connections that leave no room for error. Insulation Piercing Connectors have become an integral part of this field, especially in the development of aircraft wiring and avionics systems.

In environments where weight and space are critical, Insulation Piercing Connectors offer a lighter and less intrusive alternative to traditional connectors. Their ability to provide a strong electrical connection without the need for additional connectors or coring tools is advantageous, especially in tight spaces within aircraft structures.

Aerospace engineers value the reliability and long-term stability of Insulation Piercing Connectors, as extreme temperatures and vibrations can compromise electrical connections in the harsh conditions of high-altitude flight. By utilizing IPCs, the aerospace industry can maintain its commitment to safety and precision, ensuring that passengers and crew can communicate without interruption and utilize functioning avionics.

Aircraft Wiring

In aerospace applications, Insulation Piercing Connectors are used to connect wiring systems within aircraft. These connectors must meet stringent safety and reliability standards to ensure the aircraft’s electrical systems function correctly. IPCs provide secure connections that can withstand the extreme conditions encountered during flight, such as high vibration levels and temperature variations.

Spacecraft

For spacecraft, the demands on electrical connectors are even more rigorous. Insulation Piercing Connectors are used to connect various electrical systems within spacecraft, providing reliable connections that can endure the harsh environment of space. The durability and reliability of IPCs make them indispensable for aerospace applications, where failure is not an option.

Renewable Energy Integration: Insulation Piercing Connectors in Solar and Wind Energy Facilities

The renewable energy industry is a beacon of technological advancement, and Insulation Piercing Connector contributes significantly to the installation and maintenance of solar and wind energy systems.

Solar panel arrays and wind turbines consist of many electrical connections that must be carefully installed and maintained to ensure optimal energy production. IPC provides a fast and safe method of connecting cables while also protecting the cable insulation from potential damage.

In wind energy, Insulation Piercing Connector is used for batwing connectors – complex electrical connections on the blades of wind turbines. ipC technology provides a non-intrusive way of connecting the wires of the lights that encircle the blades, which is vital for safe navigation at night, with minimal impact on the blade surface.

For solar, where installations typically cover large areas, IPC speeds up the assembly process and minimizes damage to the protective coating of the solar panels, thus improving the overall efficiency of the system. IPC

is an unsung hero in every sector of the industry, providing solutions that are far-reaching and impactful. From grid wonders to innovative wings for energy production, their impact is clear and their value is immeasurable.

Solar Power Systems

In the renewable energy sector, Insulation Piercing Connectors are essential for solar power installations. These connectors are used to connect solar panels to inverters and other electrical components, ensuring efficient power transmission. IPCs simplify the installation process and provide durable connections that can withstand outdoor conditions, making them ideal for solar power systems.

Wind Turbines

Wind energy systems also benefit from Insulation Piercing Connector technology. In wind turbines, IPCs connect the electrical components within the turbines, ensuring reliable power transmission from the turbines to the grid. The ability of IPCs to withstand environmental stressors such as wind, rain, and temperature changes makes them well-suited for wind energy applications.

WZJ INSULATION PIERCING CONNECTORS

WZJ was established in 2004 and has been manufacturing Insulation Piercing Connectors since 2015 and has experience in many international projects.

Here are some of the factors that make WZJ one of the best manufacturers and why you should buy IPCs from WZJ.

- Product Quality and Reliability: WZJ produces high-quality Insulation Piercing Connectors that are reliable and durable.

- Compliance and Certification: WZJ Energy ensures that the Insulation Piercing Connectors comply with relevant industry standards such as NFC 33-020, and EN-50483, giving customers confidence in the quality and safety of their products.

- Product Range: WZJ Energy offers a wide range of Insulation Piercing Connectors for 1kv power lines to meet various application requirements.

- Research and Development: WZJ Energy invests in research and development to continually improve the design, performance, and reliability of its Insulation Piercing Connectors to ensure they remain competitive in the marketplace.

- Customer Support: WZJ Energy offers strong customer support including technical assistance, flexible OEM with sticker, and after-sales service, which is important to customers looking for reliable application solutions.

CONTACT US

Conclusion

Insulation piercing connectors are a versatile and reliable solution for a wide range of electrical connection needs. From utility and telecommunications sectors to automotive, aerospace, and renewable energy applications, IPCs offer numerous benefits, including ease of installation, reliability, and durability. As technology advances, the applications of IPCs are likely to expand even further, solidifying their role as a cornerstone of modern electrical systems.

FAQs

What are insulation piercing connectors?

Insulation piercing connectors (IPCs) are specialized connectors that pierce the insulation of electrical cables to establish a secure connection without stripping the insulation. They are used in various industries for their reliability and ease of installation.

How do IPCs benefit electrical distribution systems?

In electrical distribution systems, IPCs provide secure and durable connections for overhead and underground power lines. Their ability to connect wires without stripping insulation reduces installation time and labor costs.

Are IPCs used in renewable energy systems?

Yes, IPCs are widely used in renewable energy systems such as solar power installations and wind turbines. They ensure efficient power transmission and provide durable connections that can withstand outdoor conditions.

Can IPCs be used in harsh environments?

Yes, IPCs are designed to withstand harsh environments, including extreme temperatures, moisture, and vibrations. This makes them suitable for applications in automotive, aerospace, and utility sectors.

What makes IPCs suitable for telecommunications?

IPCs are ideal for telecommunications due to their ability to pierce insulation without damaging conductors, ensuring high-quality signal transmission. They are used in network cabling and fiber optic networks to provide reliable and secure connections.

Website: https://www.wzjelec.com/

Insulation Piercing Connectors: Piercing Connector – wzjelec.com

Email: rose@sunjelec.comAuther: Leb