Which Cables Are Suitable for Insulation Piercing Connectors: 3 Main Types

Insulation Piercing Connectors (IPCs) are revolutionizing the way we think about electrical connections. They offer a quick, reliable, and safe method of connecting insulated cables without the need for stripping the insulation. However not all cables are created equal, and choosing the right type for IPCs is crucial for ensuring optimal performance and longevity. In this article, we’ll delve into which cables are best suited for insulation piercing connectors and why they are the top choices.

What are Insulation Piercing Connectors?

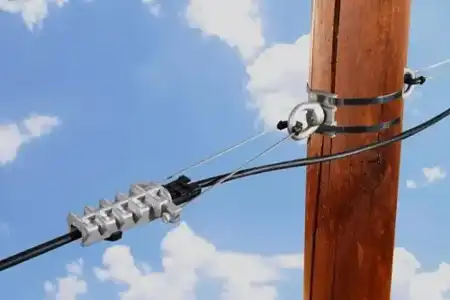

Insulation Piercing Connectors are devices designed to connect electrical cables without the need for stripping the insulation. They have sharp teeth that pierce through the insulation and make contact with the conductor, providing a secure electrical connection.

How do IPCs work?

IPCs work by using a compression mechanism that forces the connector’s teeth through the cable’s insulation into the conductor. This creates a reliable electrical connection while maintaining the insulation integrity around the rest of the cable.

Key Features of Suitable Cables

Conductor Material

The conductor material is vital for compatibility with IPCs. Copper and aluminum are the most commonly used materials due to their excellent electrical conductivity and mechanical properties.

Insulation Type

The insulation type affects the performance and safety of the connection. Common insulation materials include cross-linked polyethylene (XLPE), polyvinyl chloride (PVC), and ethylene propylene rubber (EPR).

Cable Size and Compatibility

Choosing the right cable size is essential for ensuring a secure connection. IPCs are designed to accommodate a range of cable sizes, so it’s important to select cables that fit within the specified size range.

Suitable Cable Types for IPCs

Insulation Piercing Connectors (IPC) are mainly used to connect protected low-voltage overhead lines.

There are 3 main types of LV-ABCs used in conjunction with Insulation Puncture Connectors.

1. Low Voltage Cables

XLPE Insulated Cables

XLPE (Cross-Linked Polyethylene) insulated cables are popular for their high thermal resistance and excellent electrical properties, making them ideal for IPCs in low-voltage applications.

PVC Insulated Cables

PVC (Polyvinyl Chloride) insulated cables are widely used due to their durability and cost-effectiveness. They provide good insulation and are suitable for a variety of IPC applications.

2. Medium Voltage Cables

EPR Insulated Cables

EPR (Ethylene Propylene Rubber) insulated cables are known for their flexibility and high insulation resistance. They are suitable for medium voltage applications where IPCs are used.

3. High Flexibility Cables

Silicone Rubber Insulated Cables

Silicone rubber insulated cables offer high flexibility and thermal stability, making them ideal for applications where cables need to be bent or twisted frequently, and are compatible with IPCs.

3 Main Types of LV Cables Suitable for Insulation Piercing Connectors

Self-supporting LV-ABC lines

The self-supporting system consists of 4 insulated aluminum conductors. All 4 conductors have the same mechanical strength and nominal cross-sectional area. The system can be made up of 1 or 2 additional insulated aluminum conductors with a cross-sectional area of 16 mm2 or 25 mm2 for use as wires or for street lighting.

All 4 conductors are subjected to the same load when the line is tensioned. The service line of all 3 LV-ABC systems is also normally self-supporting and consists of 2 to 4 factory-bundled insulated aluminum conductors with a cross-sectional area of 16 mm2, 25 mm2, 35 mm2.

LV-ABC line with insulated neutral conductor

The LV-ABC line with insulated neutral, also known as the “French system”, consists of 3 insulated aluminum phase conductors and an aluminum neutral (mainly Audrey), also insulated. The system can consist of one or two additional insulated aluminum conductors with a cross-sectional area of 16 mm2 or 25 mm2 for control lines or street lighting. the three-phase conductors have the same mechanical strength and nominal cross-sectional area. The neutral wire is also a suspension device with higher mechanical strength. When tensioning the line, only the neutral wire, which is the suspension, is subjected to the load.

LV-ABC line with exposed neutral messenger

The LV-ABC line with bare neutral, also known as the “Finnish system”, consists of 3 insulated aluminum phase conductors and an uninsulated aluminum neutral. The system can consist of one or two additional insulated aluminum conductors with a cross-sectional area of 16 mm2 or 25 mm2 for use as conductors or street lighting. The phase conductors have the same mechanical strength and nominal carrying surface. Neutral conductors are at the same time suspension units with higher mechanical strength. When tensioning the line, only the neutral conductor, as the suspension unit, is subjected to the load.

WZJ Insulation Piercing Connectors

WZJ offers a range of Insulation Piercing Connectors (IPC) designed for overhead low-voltage insulated and bare cable connections.

WZJ Insulated Puncture Connectors are used in a wide range of applications due to the following advantages.

- Easy and fast installation: WZJ Insulated Puncture Connectors are designed for easy and fast installation, eliminating the need to strip or cut the cable sheath when connecting cables, thus saving time and labor costs during the cable connection process.

- Reliable Electrical Connection: WZJ Insulated Puncture Connectors feature powered piercing teeth that allow a steady flow of current. WZJ Insulated Puncture Connectors provide a safe and reliable electrical connection without the need to strip the cable insulation, reducing the risk of error and ensuring consistent performance.

- Cable Type: WZJ Insulated Puncture Connector contacts have air vents made of tin-covered AL teeth for use with CU and AL conductors.

- Cable Range: WZJ has a full range of overhead cable insulated strain relief connectors for 1KV power lines, from 1.4mm2 to 400mm2.

- Weatherproof and Durable: WZJ Insulated Puncture Connectors are constructed with UV-resistant rubber caps and durable polymer materials to withstand harsh environmental conditions.

- Rust and Corrosion Resistance: WZJ Insulated Puncture Connectors utilize stainless steel bolts and washers designed to prevent rust and corrosion.

- Type Testing: WZJ Insulated Puncture Connectors are type-tested to NFC 33-020, EN 50483 by an independent laboratory.

Overall, WZJ Insulated Puncture Connectors are suitable for outdoor overhead line applications to ensure long-term performance and reliability.

The manufacturers of WZJ offer a convenient and reliable solution for making safe electrical connections in a wide range of applications.

Contact us

Conclusion

Choosing the right cables for use with insulation piercing connectors is essential for ensuring reliable, safe, and durable electrical connections. By understanding the key features of suitable cables and their applications across different industries, you can make informed decisions that enhance the performance and longevity of your electrical systems.

FAQs

1. What materials are commonly used for cables with IPCs?

Copper and aluminum are the most common materials due to their excellent electrical conductivity and mechanical properties.

2. Why is insulation type important for IPC compatibility?

The insulation type affects the performance and safety of the connection, with materials like XLPE, PVC, and EPR offering different benefits.

3. Can IPCs be used with high-voltage cables?

Yes, IPCs can be used with high-voltage cables, provided they are designed to handle the specific voltage levels and insulation requirements.

4. What are the benefits of using IPCs in renewable energy systems?

IPCs provide efficient and reliable connections for components in renewable energy systems, enhancing power generation and distribution.

5. Are IPCs suitable for use in automotive applications?

Yes, IPCs are widely used in automotive engineering to connect various electrical components, ensuring reliable and high-performance connections.

Website: https://www.wzjelec.com/

Insulation Piercing Connectors: Piercing Connector – wzjelec.com

Email: rose@sunjelec.comAuther: Leb