PG Clamp FAQs: Answering 25 Questions to Resolve All Your Queries

PG Clamps have become a necessity for power transmission. Hence, a proper understanding of PG Clamps can save your loss and the company will have a strong impact on its competitors.

Our technical team has designed all the questions you may have about PG Clamps-related business and we have tried our best to answer them in a way that removes all your doubts and misconceptions.

When you say the word “PG Clamps” and want to know everything about it, this guide is your final stop.

What Is PG Clamp?

PG clamps, also known as Parallel Groove clamps, are essential components in the electrical and telecommunication industries. These clamps securely connect and fasten wires, ensuring stable electrical connections and reducing power loss.

How Do PG Clamps Work?

PG clamps function by creating a secure grip around conductors. The parallel grooves in the clamp provide a stable connection, ensuring that the wires remain firmly in place. This connection minimizes resistance and ensures efficient power transmission.

Why Are PG Clamps Important?

PG clamps are vital for maintaining the integrity of electrical systems. They prevent wires from slipping and ensure that connections are stable and reliable. This stability is crucial in high-voltage and high-current applications, where even a slight loss of connection can lead to significant issues.

PG Clamp FAQs

Q1. Are your PG clips coated with an oxide inhibitor?

Yes, the PG clips are coated with an oxide inhibitor (commonly known as grease) to prevent oxidation of the copper-aluminum connection. Corrosion inhibitors have a wide range of roles to play in slowing down the rate of corrosion of gold centimeters and can extend the life of metals in many industrial applications. Our technical team defines a corrosion inhibitor as a substance that is included in the corrosion life cycle, in the right concentration to reduce the rate of corrosion of the metal.This all happens without making any significant changes to the corrosion agent.

Thus, thanks to the corrosion inhibitor, the conductors are prevented from rusting. As a result, the connection between the conductors is not disturbed, which means that there is no power loss and the efficiency of the product is not compromised.

If the PG clamps are not greased, the clamps will react with moisture in the air and begin to rust. It will reduce its efficiency, weaken the clamp in the long run, and may break.

Q2. What is the alternative to the PG Clamp?

An alternative to the PG Clamp is the Wedge Connector. Wedge connectors do not come with bolts. They control all stress limits, including physical and electrical stresses that other connectors cannot withstand or control. Like the PG clamp, it reduces power loss and produces a stable, efficient current throughout the line.

An acceptable temperature rise means there will be less technical loss. Increased contact area between conductor and wedge connector, resulting in increased efficiency.

No oxidation at the connection interface. The presence of a locking tab prevents the wedge from loosening after it has been driven into place.

Installation takes very little time. The mounting method is very simple and foolproof; therefore, the operator is not fatigued by a series of installations; this means that the repeatability and reliability of the mounting process are guaranteed.

Q3. What materials are commonly used in the manufacture of PG Clamps?

PG clamps are often referred to as non-tensioned bolt connectors and they are commonly used in overhead transmission networks. They are used for no-load connections of conductors made of various materials.PG clamps are manufactured from a variety of materials, commonly aluminum, copper, stainless steel, or galvanized steel.

Other sub-components of the clamp, such as bolts, nuts, and all types of washers, should be made from grade 316 stainless steel. Generally, no or very little current passes through the nuts or bolts of PG clamps.

Copper components shall have the guidelines associated with AS2738. For stainless steel components, the 316 grade of AS2837 shall be followed.

Q4. How do I install a PG clamp on a cable?

First of all, we need to have the right size of PG clips, do not cut the stranded wires from the conductor if the right size is not available.

The next step is to prepare a correct set of PG clamps along with the conductors. This is done by brushing (white brush for aluminum clamps and black brush for copper clamps) the contact surfaces to remove the oxide layer.

We then need to move on to the next stage by lubricating the brushed area and making sure the contact surface is completely covered.

Now we must use the right side of the jig to mount the conductor on it. Make sure the conductor is fully seated in the groove of the fixture.

Next, it is time to tighten the bolts to the required values as stated on the PG fixture nameplate.

For fixtures with single bolts, apply the torque values mentioned. For fixtures with two-bolt fastening, tighten the bolts progressively in sequence. It is best to tighten the center bolt first, then the outer bolts. You should tighten them at least four to five times in this order.

Q5.What should I pay attention to when installing PG clamps?

Installing the PG Clamp is not a difficult task once you have the correct clamp dimensions required. It is recommended that the PG Clamp be installed by a professional or qualified person; this person should follow safety protocols to ensure product integrity. The technically qualified person performing the PG Clamp installation should be aware of the procedures associated with the installation, hazards, and operation. At the same time, the technician should be familiar with the technical terminology of the PG Clamp and he/she should refer to the safety protocols to perform the work. According to the standard, the personnel should have the ability to complete the installation process suitably.

Q6. What factors affect the performance of PG clamps and their reliable connection?

This depends mainly on the properties of the material (metal). In addition to the material of manufacture, different factors determine the performance of PG clamps and their reliable connection, such as pressure, temperature, tension, and time.

Wire creep occurs at high pressures, and the degree of wire creep produced in PG clamps that thin the wire at high pressures is quite high. As a result, the PG clamp grip is reduced, resulting in a lost and unreliable connection. All of these factors are directly related. As the pressure on the wire increases, the temperature automatically rises. If the temperature rises, this means that more creep occurs, which ultimately leads to looser clamping and connection of the wire by the PG clamp.

To ensure full performance and greater grip, sufficient external force should be applied during installation. This is necessary because enough force is needed to create the proper pressure to prevent the wire and PG Clamp from loosening. When the external force is gone, the PG clip creates consistent pressure between itself and the wire to compensate for wire creep. The less the wire creeps, the stronger the connection.

Q7. What are some common practical uses for PG clamps?

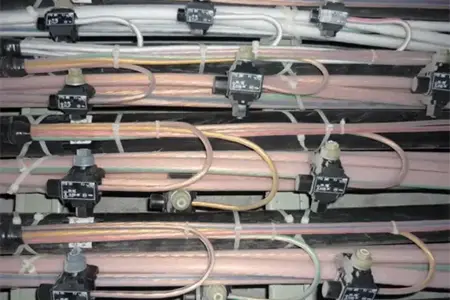

Parallel groove clips are used to connect thin wires such as aluminum or steel stranded wires where they cannot be subjected to high voltage or stress. pg clips are useful for jumper connections on bent towers and poles. They are used for T-wiring at the free-end connections of the mains.

PG clips are part of complex switches, transformers, and branch wiring. You see a small box on an overhead power line; this small box is a PG clamp. These clamps provide stable pressure and current to the connecting wires and are easy to install and remove.

Q8.What is the recommended method for selecting PG clamps?

Unfortunately, there is none.

You do not have any recommended method for selecting the right PG clamp. It is entirely up to your engineer to check and analyze which type of fixture is suitable for the connection.

You can simply consult a professional to help you select the right parallel groove clamp. However, PG clamps have standard manufacturing measures and companies must keep these measures in mind to manufacture PG clamps accordingly.

Q9. What tools should be used to install the PG Clamp?

The PG Clamp mounting tool consists of a connector frame and a support bar attached underneath the frame.

The connector frame has a mount that consists of two mechanisms, including the leads and the PG Clamp.

The PG clamp mechanism has brackets, arms, cleats, and rods, all of which are secured to the connector frame.

The lead mechanism has a connecting rod, an operating arm, a bolt on the rod, and a support frame attached to the connector frame.

As the name suggests, the support bar of the mounting tool supports the entire device.

The support bar helps bring safety because it is made of non-conductive material, meaning that current cannot pass through it.

All of these structural components must be made of high-quality aluminum or aluminum-silicon alloys to minimize electrical leakage.

Q10. What type of conductor is best suited for the PG Clamp?

The PG Clamp is 100% suitable for all types of conductors including zebra conductors, panther conductors, rabbit conductors, dog conductors, wolf conductors, and mouse conductors.

For all of these types, it works the same; however, their installation may vary.

Although these conductors have different names to distinguish them from each other so that they can be quickly and easily remembered, they belong to the same category.

Most of them are made of aluminum and steel and have different current carrying capacities. These differences in conductor current-carrying capacity do not limit the use of PG clips; this increases the versatility of their use.

Q11. What are the different sizes of PG Clips?

PG clips come in different sizes, but the most common size is 0-5 inches. For ACSR conductors, the optimal PG clamp size range is 7mm to 18.2mm in diameter and for AAAC conductors, the PG clamp size range is 9mm to 13.2mm in diameter. you can get parallel groove clamps in different sizes and varieties from your supplier depending on your needs.

Seek products from a reliable company like WZJ, which manufactures and supplies the best quality PG clamps in various sizes.

Q12.How do I know if the torque applied when mounting the PG Clamp is sufficient?

It is indicated on the PG Clamp how much torque it can withstand. The PG Clamp consists of different parts, each of which needs to be fixed and slotted by high-precision bolts. During installation, the operator uses one hand to hold the clamps and the other hand to hold the bolts. The same goes for balancing weight and posture.

This is not easy for the operator to do. For proper tightening, use a torque wrench rather than a power gun. Adjust the torque wrench to the specified torque value before use.

NOTE: If your PG clamp has 2 or 3 bolts, do not tighten the bolts one by one. Perform all of these operations at the same time because if you perform them sequentially, the first bolt will be lost and the connection will be lost.

Q13. What are the qualities of a good PG clamp?

The quality of a parallel groove clamp depends on the material from which it is manufactured, in most cases an aluminum-silicon alloy. The number of impurities and the silicon content determine not only the electrical efficiency but also the mechanical efficiency.

Some PG fixtures have shrinkage, irregular shape, and uneven surfaces due to defects in casting, which reduces the overall quality of parallel slot fixtures.

The grooves of some PG wire clamps seem to be quite deep compared to the thickness of the wire, which makes them low quality and inefficient because the wire cannot pass through the grooves. Connection points must be free of rust and dirt to ensure less friction between the contact point and the wire.

Q14. What are the benefits of PG clamps?

PG clamps function optimally to transfer the correct amount of current between two wires running parallel to each other. Not only are they used to connect wires where a load cannot be carried, but they also provide low resistance.

Less resistance means less power loss.

Reduced supply losses increase the efficiency of working machinery and appliances.

Higher output power improves the efficiency of transformers and direct power stations.

Q15. Can I reuse the already installed PG clamps?

No, PG clamps are not reusable.

Unfortunately, you cannot reuse an installed PG clamp even if it has a slight defect. The main reason behind this is that the grooves wear out over time and the smoothness of the clamping surface decreases during disassembly. So it is advisable to buy a new PG clamp instead of using an already installed PG clamp as it will not work efficiently.

This will make the PG Clamp less economical, but they are affordable and you can easily purchase them for each new installation.

Q16. How does the PG Clamp withstand physical damage?

Aluminum tape or wire is wrapped around the leads or copper wires to reduce friction and prevent damage to the PG Clamp.

We understand that due to increased pressure and greater wire creep, temperatures may rise, causing the wire to burn and melt the PG Clip. To avoid this, make sure the grooves are free of rust and that sufficient external force is applied during installation. The correct mounting torque determines the fate of the PG clamp and makes a difference in its efficiency.

Aluminum straps, rust-proof grooves, and external force then play a role in reducing physical damage to the PG Clamp.

Q17. What is the load range that PG Clamps can withstand?

The clamping force on the conductor by an unloaded parallel groove wire clamp is always less than 10% of the conductive force on the conductor, so the conductivity should be higher than the resistance of the contact wire.

The resistance change index is based on electrical standards for maximum stability of the PG clamp. This index helps you determine whether the power supply is normal or not. Whenever a short circuit occurs, the circuit remains safe because the PG clamp does not fail before the wire.

These measures are recommended by international standards for electrical appliance manufacturing.

Q18. What specific external factors can cause damage to the PG clamp?

The main method to prevent damage to the PG clamp is to apply a calculated external torque to the PG clamp.

If rust appears in the grooves, apply an antioxidant and make sure the recessed sugar is dry, as this will directly affect the wire connections.

The current load of the power supply must be within the limits of the circuit or lane.

Q19.Can PG clamps be used for overhead and underground connections?

Yes, you can use PG clamps for both overhead and underground connections.

They are compatible with both types of connections because they are made of an aluminum-silicon alloy that conducts current very well throughout the line and circuit.

Q20.Why do you prefer you over other PG clamp manufacturers?

WZJ is a reliable and trustworthy company that produces high-quality products with PG clamps that meet the standards of the General Technical Requirements for Power Fixtures.

Our products have specific advantages over other competitors’ products as follows.

The body of Parallel Groove Clamps is made of tensile ductile material.

The bolts are manufactured by strict international standards and are rust-resistant.

The nuts of the bolts are also hexagonal nuts measured according to international standards.

The PG clamps are manufactured without an oxidized layer on simple washers.

The spring washers also meet the standard values, making the PG Clamps a reliable product.

Q21. What are the specifications of PG Clamps?

PG clamps should be made of high-quality oxidation-resistant metal alloy or pure metal.

For overhead connections, they must work well in all types of weather.

Arcing should not loosen the connection, so always look for high-quality PG clamps.

Notches and wire sizes must complement each other. If the wire is not the correct size, it will not fit through the grooves of the clamp.

The required external force or torque must be indicated on the parallel clamp.

Nuts and bolts should be hexagonal.

Above all, remember that the PG clamps you obtain meet standard conditions and are tested before use.

Q22. Are PG clamps suitable for Panther conductors?

Yes, you can use PG clamps on Panther conductors, which are ACSR conductors with BS-215 standard values. They are made of aluminum and the aluminum used to make these conductors is approximately 200mm2.

Panther conductors also contain 7 pieces of steel and 30 pieces of aluminum. These conductors are suitable for high-power supplies and allow easy adjustment of the PG clamp position.

Q23. What are some common applications for PG clamps?

PG clamps have a variety of applications due to their reliability and easily adjustable construction. They are not complicated and they provide smooth current flow between different conductors.

PG clamps are best suited for the following applications.

For connecting ground wires

For all types of steel core aluminum stranded conductors

Can be used in transformers

Play a great role in the entire transmission line

Q24. Can I use PG clamps for fiber optic ground wire (OPGW)?

Yes, you can use PG clips for fiber optic ground wiring (OPGW).

Fiber optic ground wires are best when it comes to conducting power from one place to another.

They are best because they provide power quickly and are more efficient because there is relatively little power loss due to leakage in this type of cabling.

PG clips fulfill the purpose of optical grounds that need to withstand high voltage.

Q25. Can I purchase PG clamps in different designs?

Yes, you can request different designs of PG clamps.

They are available in three forms: single bolt, 2 bolts, 3 bolts, and up to 8 bolts PG clamps, all of which have the same mounting procedure, principle of operation, and base material.

The most commonly used and available PG clamps are the single-bolt, 2-bolt, and 3-bolt PG clamps.

Please remember not to rotationally tighten the 2 and 3 bolts of the PG Clamp. They need to be tightened simultaneously by the operator with both hands.

Contact us

If you want to learn more about PG clamps or need our assistance, please feel free to contact us!

Related Links:

PG Clamps Product Page

Contact Us

Website: https://www.wzjelec.com/

Email: rose@sunjelec.comAuther: Leb