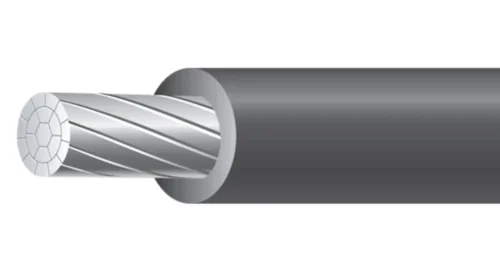

Aluminum Cable Wiring Guide:How to properly connect and terminate aluminum cables

Aluminum cables are widely used in electrical installations due to their cost-effectiveness and lightweight properties. However, connecting and terminating aluminum cables requires special attention to ensure proper electrical conductivity and prevent potential hazards.

What is a good electrical connection?

A good electrical connection should be able to conduct current safely at low temperatures, thus saving energy. It should also be able to last for many years (up to 30 years or more).

On the other hand, a poor electrical connection can lead to poor current conduction at high temperatures, resulting in heat loss and even fires. For a building consisting of many joints and terminals, the heat loss from each connection adds up to a huge amount. Even if each connection loses a few watts, the loss 24 hours a day, 365 days a year, combined with the loss of many connections, equals huge heat loss and waste.

Aluminum Conductors as an Alternative to Copper

In terms of electrical conductivity, aluminum is the best alternative to copper in terms of commercial value and engineering performance. Compared to copper, aluminum has only one-third the specific gravity of copper but is 60% more conductive. Aluminum is also about 70% less expensive than copper. Because of their light weight and relatively low cost, aluminum conductors are widely used in electrical projects today.

However, when aluminum comes into contact with copper, it can corrode in a short period, leading to damage at the point of contact. Since aluminum and copper have different electrical potentials and expansion rates, exposure to hot and cold cycles in the air increases resistance and corrodes contact points. This phenomenon is known as the coupling effect or galvanization.

Due to the lack of suitable connectors, many early installations of aluminum conductors fail after a short period of use. This has led to a reluctance on the part of consulting engineers, contractors, and homeowners to use aluminum conductors, making their use in indoor wiring less common.

Bimetallic cable glands and connectors

However, this changed with the invention of friction-welded bimetallic lugs and connecting wires in Europe, which are now widely used. Bimetallic lugs are today’s best solution to the problem of contact between aluminum and copper. Tenaga Nasional Berhad (TNB) has been using aluminum cables and bimetallic lugs for the past 20 years without any problems. This proves that aluminum conductors are as high quality and reliable as copper conductors.

In the international market, quality bimetallic lugs and connectors are mainly produced in Europe, with the best quality products coming from France. The governing standard is HN 68-S-90, entitled “Insulated cables with aluminum conductors for deep indentation connections”. The standard covers material specifications, connector dimensions, friction welding area, crimping methods and dies, type tests, and acceptance tests. It is now internationally recognized and used.

Equally important and widely accepted is the IEC test standard IEC 61238-1, entitled “Compression and mechanical connectors for power cables with rated voltages up to 30 kV”, which is also used by TNB and type tested. Therefore, bimetallic lugs conforming to these standards and type tests can be used in electrical projects using aluminum cables.

Bimetallic lugs are manufactured by fusing aluminum and copper in a process called friction welding. This process is accomplished by rotating the aluminum and copper on a machine, causing the two metals to rub against each other and generate high heat. At this stage, a strong force is applied to weld the two metals together.

A good quality friction weld provides a perfect seal between the two metal surfaces without any air gaps, thus preventing contact corrosion. A good and sufficient weld area also contributes to the electrical conductivity and mechanical strength of the connection. The manufacturing process is easy to understand, but the actual production of bimetallic connectors is a complex process that requires the latest mechanical technology, technical skills, and expertise as well as proper quality control.

Bimetallic lug standard in Malaysia

To cater for the application of bimetallic cable glands on aluminum cables, the Malaysian Bureau of Standards (BBS), in collaboration with the Standards Writing Organization (SWO) TEEAM, has developed MS 2584:2014 – Specification for Material, Marking, Dimensioning and Type Testing of Crimped Copper-Aluminium Bimetallic Splices for XLPE Insulation and Compact Aluminium Conductors for Single and Multi-Conductor Power Cable Applications up to 36 kV.

Currently, bimetallic lugs conforming to the IEC 61238-1 type test and conforming to MS 2584:2014 are available in Malaysia with accompanying tools and molds and are commonly used in electrical projects. However, many non-compliant bimetallic lugs are also imported into Malaysia. These non-compliant lugs do not meet the specifications and molds of compliant lugs. They are usually smaller in size and poorly manufactured, resulting in higher temperatures in the connection area. The use of these lugs leads to heat loss, energy wastage, and fire risk.

For a good connection of aluminum cables, bimetallic lugs that have been type-tested to IEC 61238-1 or MS 2584:2014 must be specified and used. In any connector termination or splicing, it is equally important to select matching tools and dies to achieve a perfect connection. For aluminum cable connections, indentation dies are commonly used. These are primarily hand-operated hydraulic tools, but electric pumps are also popular for their quick and easy operation.

Finally, the human factor is just as important in achieving a good electrical connection. Wiremen and electricians must be willing to follow the manufacturer’s instructions. For larger connectors, crimping should be done several times or according to the manufacturer’s instructions. In Malaysia, standard-compliant molding tools are now readily available. Therefore, good connections can be easily achieved when the correct connectors and tools are used and procedures are followed.

Frequently Asked Questions (FAQ)

Q1: Can I use the same connectors for aluminum and copper cables?

A1: No, it is important to use connectors specifically designed for aluminum conductors to ensure compatibility and prevent potential issues such as galvanic corrosion.

Q2: Why is an anti-oxidant compound necessary for aluminum connections?

A2: Aluminum is prone to oxidation, which can hinder electrical conductivity. The anti-oxidant compound helps minimize oxidation and ensures a stable and long-lasting connection.

Q3: Can I use regular electrical tape to insulate aluminum connections?

A3: It is recommended to use electrical tape or heat shrink tubing specifically designed for electrical connections to provide proper insulation and protection.

Q4: Are there any specific torque values for tightening aluminum connections?

A4: Yes, it is important to follow the manufacturer’s instructions and use the recommended torque values when tightening bolts for aluminum connections.

Q5: Do I need to periodically check and maintain aluminum connections?

A5: Regular inspections and maintenance are recommended to ensure the integrity of aluminum connections. This includes checking for any signs of damage, corrosion, or loose connections.

Website: https://www.wzjelec.com/

Product: https://wzjelec.com/product

Email: rose@sunjelec.comAuther: Leb