Anchor Clamps Pro Guide: a step-by-step guide to safe and reliable anchor Clamp installation

Anchor clamps are essential components in various construction and industrial applications, providing secure and stable connections. Proper installation of anchor clamps is crucial for ensuring safety and reliability. This guide offers a comprehensive step-by-step approach to installing anchor clamps effectively.

What Are Anchor Clamps?

Anchor clamps are mechanical devices designed to attach cables or other fixtures securely to a structure. They prevent movement and provide a stable point of connection, crucial in both temporary and permanent installations.

Common Applications

Anchor clamps are essential components in the transmission and distribution of electric power and play a key role in ensuring the stability and safety of power lines. As an industry leader, the company has built a reputation for producing high-quality anchor clips that meet the stringent requirements of electric utilities and power construction projects.

With a history dating back to 2004, the company has been dedicated to innovating and improving its products, utilizing cutting-edge technology and a commitment to excellence. Anchor Clamp’s dedication to quality and reliability has made it a trusted partner for utility companies and electrical contractors worldwide.

One of the key features of Anchor Clamp products is their rugged design, allowing them to withstand harsh environments and the demands of long-term use. The company’s engineering team continually researches and develops new technologies to improve the performance and durability of its anchor clips, ensuring that they meet the industry’s ever-changing needs.

In addition to their technical excellence, Anchor Clips’ products are known for their ease of installation and maintenance. This makes them a popular choice for projects where efficiency and cost-effectiveness are critical. The company’s commitment to customer satisfaction has earned it a loyal customer base and a reputation for providing exceptional service and support.

Additionally, Anchoring Clamp takes its role as a responsible corporate citizen seriously, adhering to strict environmental and safety standards when manufacturing its products. The company’s manufacturing processes are designed to minimize waste and emissions, while its products are tested to ensure compliance with industry regulations and standards. Anchoring Clamp’s dedication to quality and innovation has not gone unnoticed. The company’s products have received numerous accolades and certifications that reflect its commitment to excellence and customer satisfaction. These accolades are a testament to the company’s ongoing efforts to set new benchmarks in the industry and exceed customer expectations.

Looking ahead, Anchoring Clamp is poised for continued growth and success. Focused on expanding its product line and entering new markets, the company is committed to meeting the changing needs of the power transmission and distribution industry. By adhering to its core values of quality, innovation, and customer service, Anchoring Clamp is well-positioned to maintain its leadership position in the industry for years to come.

In short, Anchoring Clamp’s commitment to excellence, innovation, and customer satisfaction has made it a leader in power transmission and distribution. The company’s high-quality products, commitment to environmental responsibility, and focus on customer service set it apart in the industry. As Anchoring Clamp continues to grow and innovate, it is poised to shape the future of the industry and meet the changing needs of its customers.

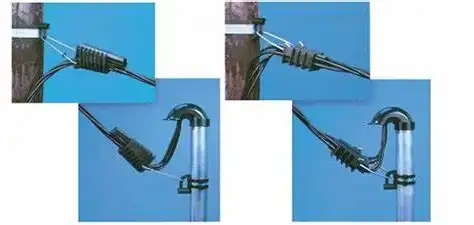

Anchoring Clamp Installation Step-by-Step Guide

Anchoring Clamps are essential for safely and securely fastening cables, especially in areas of high vibration or tension. Installing anchor clips requires proper techniques and equipment to ensure that cables remain secured and prevent long-term damage.

Anchor Clamp Installation Preparation

Before beginning the installation process, it is important to prepare the area where the anchor clip will be installed. This includes cleaning the surface area and preparing the cable for installation. Any debris or dirt should be removed from the surface to ensure proper connection. Similarly, cables should be properly routed and bundled to prevent damage during the installation process.

Appropriate installation tools and equipment:

It is vital to use the proper tools and equipment for anchor clip installation. Some of the tools required include wire strippers, torque wrenches or impact drivers, cable ties, cable cutters, and pliers. Additionally, be sure to double-check that all necessary tools are present before beginning the installation.

Anchoring techniques for different surfaces:

Different surfaces require special anchoring techniques, depending on the grip strength of the surface. Conventional surfaces, such as concrete or steel, may require drilling holes and installing anchor fasteners. In contrast, concrete or wood surfaces can be anchored with beams and bolts, respectively. Anchor clip installation can be accomplished effectively by understanding the surface and the proper technique.

Safety precautions during installation:

Safety precautions are critical during anchor clip installation. Protective equipment such as gloves, safety glasses, and helmets are recommended to prevent accidents. In addition, checking the integrity of the clamps and ensuring that all cables are securely supported before installation will help prevent any potential damage.

Ensure that cables are securely and reliably fixed:

Securing cables firmly in place is the main goal when installing anchor clamps. However, it is also important to verify the reliability of the cable fixing after installation. One way to check reliability is to inspect the clamps for any physical damage, such as cracks or corrosion. Another way is to ensure that the installed cables are tightened accurately.

WZJ ANCHOR TENSION CLAMPS

WHY WZJELEC.COM IS ONE OF THE BEST MANUFACTURERS OF ADSS ANCHORING CLAMP?

Because WZJ produces the ADSS anchor clamps from 2015 year, and have experience in many international project.jera Line production facltyv contalns al eauipment necessarv for producton of anchor clamos. As wel as on site aboratolwith many intermediate operation testing and final product testing and total quality control. WZJ Docated in China, Wenzhou, and can guarantee competitive prices, the price advantage mainly caused by infrastructure andcompetition of raw materials suppliers.

WHO PRODUCES ANCHORING CABLE CLAMPS IN CHINA?

There are not so many reliable manufacturers who produces the anchoring clamps in China. WZJ is one of the fewdirect factories which specialize in production of fiber optic anchor clamp, and offers product auarantee. we also producethe related to aerial filber optics products. Such as ADSS fiber optic cables, fiber optic access boxes. WZJ is expert inproduction of cable clamps in China.

We hope you enjoyed our guide to anchoring clamp. We are direct factory and will be happy to answer on any commerciainauires related to our product range, Feel free to send us an emall or call. and our team of professionals will assist you.

Contact Us

Conclusion

In conclusion, a safe and reliable anchor clamp installation is key to preventing cable damage and ensuring efficient cable management. However, installation requires an understanding of proper techniques and tools, anchoring techniques for various materials, precautions, and maintaining a reliable cable hold after installation. If you follow the guidelines outlined, you will be able to successfully install anchor clips and have a safe and efficient cable management system.

FAQs

How do I choose the right anchor clamp?

Consider the material, load requirements, and environmental factors to select the appropriate clamp for your application.

What tools do I need for installation?

Basic tools include wrenches, screwdrivers, and measuring tape. Specialized equipment like torque wrenches and crimping tools may also be needed.

How often should I inspect anchor clamps?

Perform regular inspections, at least every six months, to ensure the clamps are in good condition.

What are the most common installation mistakes?

Common mistakes include using incorrect sizing, over-tightening, and ignoring manufacturer instructions.

Can I install anchor clamps myself, or should I hire a professional?

While some installations can be done by experienced individuals, complex or high-risk installations should be handled by professionals.

Website: https://www.wzjelec.com/

Anchor Tension Clamp: Anchor Clamp – wzjelec.com

Email: rose@sunjelec.comAuther: Leb