What is a Cable Tension Clamp: A Guide to Identifying 10 Types of Tension Clamps

Cable tension clamps are vital components in electrical and telecommunication networks. They ensure that cables are securely fastened and maintain the appropriate tension to avoid sagging and potential damage. This comprehensive guide will walk you through everything you need to know about cable tension clamps, focusing on identifying 10 different types.

What is a Cable Tension Clamp?

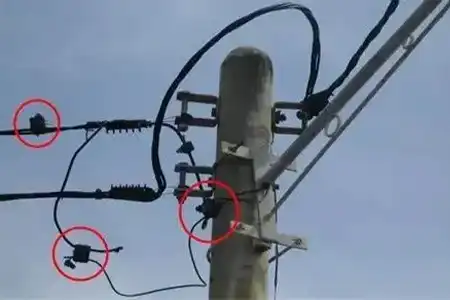

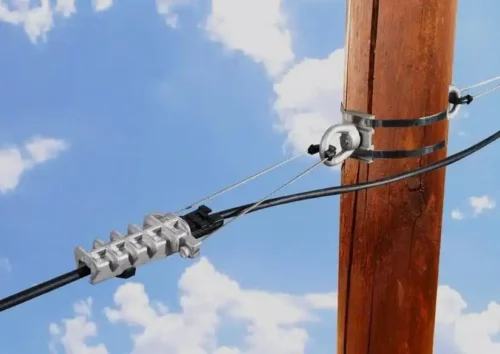

A tension clamp is a type of tensioning hardware used to complete a tensioned connection of a conductor or cable, providing mechanical support for the insulator and conductor. Most tension clamps are used to connect overhead wires to optical equipment or utility poles. Different styles of tension clamps have different body materials and clamp ring sizes. Most cable clamps are made of stainless steel and some are made of plastic. They are reliable, weatherproof, and durable.

Tension clamps should be used to provide support and ensure that the fiber or device stays in place and is properly connected. It’s as if optical fibers tend to be stronger when contracted but break quickly when bent hard. To increase efficiency and save time when laying cables, tension clips are used to make the laying process easier. In

When laying fiber optic cables above or below ground, strain gauges should be used to complete the cable assembly. To ensure a clean and correct installation, tension clamps should be used at all points in the process to hold the cables together and in place. The main parameters of the tension clamps are the diameter of the cable to be clamped and the maximum tension.

Why Are Cable Tension Clamps Important?

Cable tension clamps play a crucial role in maintaining the integrity of overhead and underground cabling systems. They ensure that cables are held taut, reducing wear and tear, minimizing service interruptions, and extending the lifespan of the cable infrastructure.

What types of cable tension clamps are available?

Hanger feeder clamps

The hanger feeder clamps are made of stainless steel and have a long service life.The hanger feeder clamps can be used for anchoring, turning, and suspending fiber optic cable lines. It is suitable for round lead-in fiber optic cables with a diameter of 3-7 mm.

S-Hook Tension Clamps

S-Hook Tension Clamps can be used on buildings, utility poles, strands with drive hooks, pole supports, national steel hooks, and other drop wire accessories and hardware.

Suitable for introducing fiber optic cables over short distances overhead. For introduction wires from 2 to 8 mm thick. Widely used for indoor installations and outdoor installations.

Plastic cable clamps

Plastic cable clamps are used to introduce fiber optic cables and are used to secure and keep the cables stretched. Typically, fiber optic cables are laid around transmission lines or on buildings with a spacing of less than 50 meters. The plastic cable clamps are designed for cables with a height of 4 mm and a width of 8 mm. The clips hold flat cables securely.

Aluminum tension clamps

This lead cable tension clamp is suitable for drive hooks, pole mounts, or other accessories. It is used for short spans (up to 150 m) of 2-6 mm diameter lead cables on intermediate poles of straight routes, and the type is selected according to the cable diameter.

Taint Clamps

Strain clips are designed to secure FRP leaded fiber optic cables with wire diameters up to 3 mm in overhead outdoor FTTH constructions. Strain clips are available for dead-end fiber optic network routes.

Cable Tension Clamps

Zigzag cable tension clamps are designed to quickly, easily, and reliably terminate ADSS fiber optic cables in access networks spanning up to 100m. A pair of wedges automatically clamps the cable inside the cone. Suitable for fiber optic cables with a diameter of 3-7 mm.

Dead-end cable pre-tensioning clamps

Configuration: one pair for terminating towers; two pairs for tensioning towers and splicing towers. Steel spiral tension clamps are characterized by high grip strength, up to more than 95% of the breaking load, little damage, and not easy to loosen. Depending on the length of the inner and outer poles, it is suitable for ADSS fiber optic cables with a diameter of 7-27 mm.

Overhead Pre-Twisted Suspension Clamp

It is used for the connection between a straight pole (tower) and ADSS fiber optic cable, and it is suitable for a straight pole (tower) with a large span and large elevation angle. The specification model of the ADSS suspension clamp is selected to correspond to the corresponding fiber optic cable diameter, load capacity, or gear length.

J-hook suspension clamp

Select the model according to the diameter of ADSS fiber optic cable, applicable to round fiber optic cable. The J-hook suspension clamps are used to provide suspension for Ø8 to 20 mm overhead ADSS cables at intermediate poles in cable runs with angles of less than 20° in access networks with spans of up to 100 m. The J-hook suspension clamps are available in a variety of sizes to suit the diameter of the ADSS cable.

S-type drop clamps with hook

The S-type lead-in clamps with hooks are designed for suspending or tensioning round or flat FTTH lead-in cables lead-in cables or telephone lead-in cables. The FTTH clamps are suitable for short outdoor spans of up to 80 m and are used for cables with diameters of less than 5 mm.

What is the best way to select cable clamps?

Suspension feeder clips, S-hook tensioning clips, plastic clips, aluminum tensioning clips, stainless steel clips, and S-lead clips with hooks are suitable for fiber optic feeder cables.8 Zigzag fiber optic tensioning clips, dead-end pre-tensioned pre-tensioned clips, overhead pre-tensioned suspension clips, and J-hook suspension clips are suitable for ADSS fiber optic cables.

If the angle of the connection is greater than 25°, it is preferable to use hanging feeder clips, S-hook tensioning clips, plastic clips, aluminum tensioning clips, stainless steel clips, figure-of-eight cable tensioning clips, or dead-end pulling pre-tensioned clips. If the angle of the connection is less than 25° or there is no angle, it is best to use overhead pre-tensioned suspension clips, J-hook suspension clips, or S-drop clips with hooks.

Advantages of Using Cable Tension Clamps

1. Enhanced Cable Stability

Cable tension clamps provide a secure grip on the cables, preventing movement and sagging. This ensures that the cables remain firmly in place, even under heavy loads or in adverse weather conditions. Enhanced stability not only protects the integrity of the cable but also maintains the overall efficiency and safety of the electrical or communication system.

2. Extended Cable Lifespan

By maintaining proper tension, cable tension clamps significantly reduce wear and tear on the cables. When cables are allowed to sag or move, they can experience friction and stress that lead to premature aging and failure. Tension clamps alleviate these issues by keeping the cables taut and secure, thereby extending their usable life and reducing the frequency of replacements.

3. Improved Network Reliability

Securely fastened cables are less likely to suffer from service interruptions and maintenance issues. When cables are loose or sagging, they are more prone to damage from environmental factors or accidental impacts. Cable tension clamps mitigate these risks by holding the cables in place, ensuring a consistent and reliable connection. This translates to fewer outages and a more dependable network, whether for telecommunications or power distribution.

4. Versatility

Cable tension clamps are highly versatile and can be used in a wide range of applications. From telecommunications to power distribution, these clamps are designed to handle different types of cables and operational environments. Whether it’s for securing fiber optic cables in a data center or holding power lines in an outdoor setting, cable tension clamps offer a flexible solution that can be adapted to various needs.

5. Cost Savings

Investing in high-quality cable tension clamps can lead to substantial cost savings over time. Although the initial expenditure may be higher, the long-term benefits include reduced maintenance costs and extended cable infrastructure lifespan. By minimizing wear and tear and preventing damage, these clamps lower the need for frequent repairs and replacements. This not only saves money but also reduces downtime, ensuring that systems run smoothly and efficiently.

Using cable tension clamps is a smart investment for anyone looking to enhance the stability, longevity, and reliability of their cable systems while also achieving significant cost savings.

Conclusion

Cable tension clamps are essential for maintaining the stability and reliability of cable networks. By understanding the different types of tension clamps and their applications, you can make informed decisions to ensure the safety and performance of your cable installations. Whether you are working on a large-scale utility project or a small residential installation, choosing the right tension clamp is crucial for success.

Frequently Asked Questions (FAQ)

What are anchoring clamps?

These clamps are designed to secure FTTH round area cables from 6 mm to 14 mm. These anchor clamps are suitable for different network configurations.

How are anchor clamps used?

The most common use of anchor clamps is for power lines between residential buildings, and industrial parks, while self-supporting insulated wires are often used for fixing.

What is the purpose of anchoring clips?

To prevent wires from dangling due to icing, breeze or gravity anchor clips can be used. In addition, the reliable installation of wires when tensioning them between transmission line supports also falls under the role of anchor clips.

How do I install an anchor clip?

Here are the steps to install an anchor clip

- Take two straps of the appropriate length

- Pass the open end of the strap through the buckle

- Locate the bracket on the pole and wrap the strap around the bracket

- Place the other end of the strap into the strapping tool and lock the tool in place.

- Tighten the strap by rotating the handle of the strap tool

- Use a knife blade to cut additional straps

- Bend the flange with a hammer

- The bracket is now installed.

Website: https://www.wzjelec.com/

Anchor Tension Clamp: Anchor Clamp – wzjelec.com

Email: rose@sunjelec.comAuther: Leb

WZJ ANCHOR TENSION CLAMPS

WHY WZJELEC.COM IS ONE OF THE BEST MANUFACTURERS OF ADSS ANCHORING CLAMP?

Because WZJ produces the ADSS anchor clamps from 2015 year, and have experience in many international project.jera Line production facltyv contalns al eauipment necessarv for producton of anchor clamos. As wel as on site aboratolwith many intermediate operation testing and final product testing and total quality control. WZJ Docated in China, Wenzhou, and can guarantee competitive prices, the price advantage mainly caused by infrastructure andcompetition of raw materials suppliers.

WHO PRODUCES ANCHORING CABLE CLAMPS IN CHINA?

There are not so many reliable manufacturers who produces the anchoring clamps in China. WZJ is one of the fewdirect factories which specialize in production of fiber optic anchor clamp, and offers product auarantee. we also producethe related to aerial filber optics products. Such as ADSS fiber optic cables, fiber optic access boxes. WZJ is expert inproduction of cable clamps in China.

We hope you enjoyed our guide to anchoring clamp. We are direct factory and will be happy to answer on any commerciainauires related to our product range, Feel free to send us an emall or call. and our team of professionals will assist you.