5 Busbars Protection Solutions – Why do you need busbars?

What is a busbar?

A busbar is a metal conductor that serves as a central hub for multiple electrical connections. It can be solid, hollow, or flexible and comes in a variety of shapes. In this blog, we will look at the types of busbars and their role in various applications.

Essentially, it is the electrical connection point where all input and output currents converge. This means that the busbar concentrates the power in one place. The number of input and output connections can be adjusted according to the power demand while always taking into account the busbar’s current carrying capacity. Busbars are an integral part of substations and are used in low-voltage (up to 400 V), medium-voltage (about 11 kV), and high-voltage (up to 765 kV and above) systems.

The role of busbars in power distribution

Bus ducts simplify complex power distribution, making it more affordable by replacing multiple conductors and reducing costs.

By providing a single node, it is easier to add protection to all incoming and outgoing connections according to the busbar connection scheme. Busbar systems include isolators and circuit breakers. In the event of a fault, the circuit breaker trips, and the faulty bus section is disconnected from the circuit.

The choice of busbar arrangement depends on factors such as reliability, flexibility, and cost. Key considerations include ease of maintenance, continuity during maintenance, and economical installation.

Busbar Programs

Because of the belief in the high reliability of busbars, busbars are usually not protected exclusively. In addition, it was previously believed that standby protection was sufficient to provide adequate busbar protection. However, when standby protection is used, issues such as loss of load and extended fault clearing times make dedicated busbar protection schemes necessary. The following are some of the major busbar schemes:

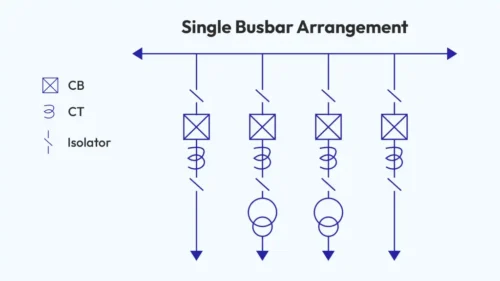

A) Single busbar arrangement

This arrangement uses two busbars and a bus coupler to connect disconnect switches and circuit breakers to the busbar. In case of overload, it allows the load to be transferred from one busbar to the other. This scheme maintains power continuity even during faults, allowing maintenance to be performed without interrupting continuity. However, the use of two busbars increases the system cost.

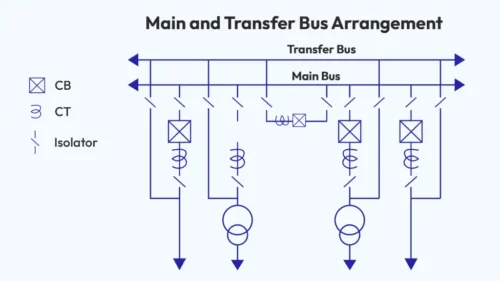

B) Main and Transfer Bus Arrangement

This arrangement uses two busbars and a bus coupler to connect disconnect switches and circuit breakers to the busbars. In case of overload, it allows the load to be transferred from one bus to the other. It maintains supply continuity even in the event of a fault and allows maintenance to be performed without interrupting continuity. However, the use of two busbars increases the cost of the system.

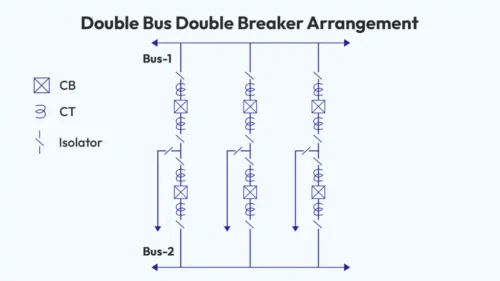

C) Dual Busbar Dual Breaker Arrangement

This option uses two busbars and two circuit breakers for excellent reliability and flexibility. It ensures uninterrupted power supply during faults and maintenance but is more costly because of the additional equipment required.

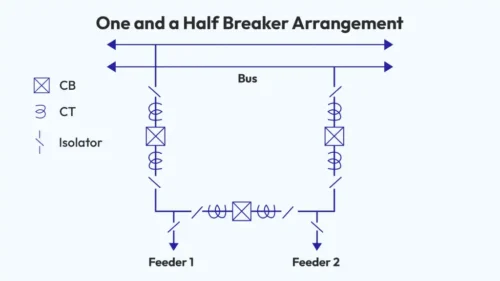

D) One-and-a-half breaker arrangement

This setup involves three circuit breakers for two separate circuits. Each circuit shares a central circuit breaker. This arrangement ensures protection against power failure and facilitates the addition of additional circuits for easy maintenance. However, this arrangement can be more expensive to maintain.

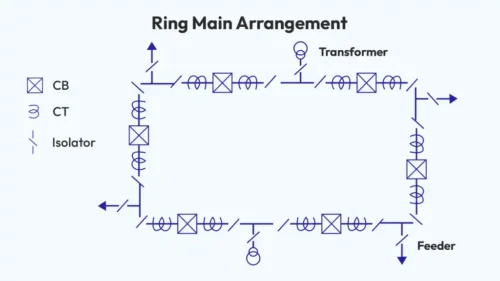

E) Ring Main Arrangement

In this arrangement, the busbar forms a ring providing two supply paths. This means that if one circuit fails, the system can still operate through the other part of the ring. This design localizes the fault to a specific section and allows maintenance of the circuit breakers without interrupting the entire supply. However, this arrangement cannot be expanded in the future because it is a closed-circuit system. Therefore, it is not the best choice for developing a system.

Application of busbar rows

Busbar rows are critical components in a variety of electrical systems, ranging from small power systems to large substations and power generation systems. Following are some of the key areas where bus bars are widely used:

1) Power Plants: In power plants, busbars are used to distribute the generated power to transformers which then transmit the power to the grid. They are essential for managing current and ensuring efficient power distribution.

2) Substations: Substations are intermediate points in the grid where the voltage level changes from high to low voltage or from low to high voltage. Busbars in substations help distribute power to individual feeders. They also play a vital role in fault management by allowing the isolation of the faulty portion without interrupting the entire system.

3) Data Centers: In data centers, busbars are used to distribute power to various servers and other equipment. They provide a flexible and efficient solution for managing the high power demands of these facilities.

4) Hospitals: The demand for power in hospitals is so high that any disruption can have serious consequences. Hospital buses ensure reliable and efficient power distribution to all areas, including critical areas such as operating rooms and intensive care units.

5) Institutions: Educational institutions, office buildings, and other large facilities use busbars for efficient power distribution throughout the premises. They help manage the varying power needs of different areas, from classrooms and offices to cafeterias and laboratories.

6) Apartments: In residential buildings, busbars are used in the main distribution panels to distribute power to individual apartments or parts of the building. They help in managing the electrical load and ensure safety by isolating faulty sections.

7) Subways and Railways: In transportation systems such as subways and railroads, busbars are used in substations to distribute power to tracks and trains. They are vital for the smooth functioning of these transportation systems.

Essentially, bus bars are used wherever efficient, reliable, and flexible power distribution is required. They help manage electrical loads, ensure safety, and reduce costs by replacing multiple conductors with a single bus bar. The choice between copper and aluminum bus bars depends on specific requirements, including electrical ratings, cost, weight, and environmental considerations.

Busbar Types

Busbars come in a variety of shapes, including rectangular, cross-section, and round. The two primary materials used in their construction are copper and aluminum. Choosing between these two types of busbars depends on a variety of factors, so let’s explore them.

Copper Busbar vs Aluminum Busbar

A busbar is a metallic conductor used as a central hub for multiple electrical connections and can be made from a variety of materials. However, the two most common materials are copper and aluminum. Both materials have their pros and cons, and the choice between the two usually depends on the specific requirements of the project.

Copper busbar

Known for its high electrical conductivity, copper is the metal of choice for applications that require excellent ductility and conductivity. Compared to aluminum, copper has better tensile strength, higher thermal expansion, and superior conductivity.

Aluminum Busbar

The strength and conductivity of aluminum depend on the alloying agent used. Its properties range from very soft to having the same strength as mild steel. Pure aluminum has 62% of the conductivity of copper, but aluminum is up to 70% lighter. This saves costs in areas such as transportation and installation. However, aluminum requires a larger conductive surface area than copper, which means that aluminum parts are larger.

Copper vs Aluminum Busbar

In terms of electrical ratings, copper outperforms aluminum in terms of power loss, voltage drop, resistance, and current carrying capacity. However, when compared on a weight basis, aluminum is more efficient. In terms of cost, copper is much more expensive than aluminum. However, the prices of both materials are greatly influenced by political and economic factors and consumer demand, leading to price fluctuations.

From an environmental perspective, both copper and aluminum are recyclable metals. Aluminum, however, has the highest recycling rate, with about 75% of it still in use. The recycling process for aluminum uses less energy than copper and is arguably more environmentally friendly.

In the case of connectors, if you choose to use aluminum, the connectors must be rated for aluminum. Those connectors that are rated for aluminum can usually be used with copper, but the reverse is not always true.

In summary, the choice between copper and aluminum bus bars depends on a variety of factors, including electrical ratings, cost, environmental sustainability, and connector compatibility. Understanding these factors can help you make an informed decision for your next busbar application.

The Imperative of Busbars

Busbars are not merely passive conduits; they are the lifelines of electrical systems. Their role is multifaceted, ensuring not only the seamless transmission of power but also contributing to the overall safety and stability of the electrical grid. Here’s why you need them:

Enhanced Efficiency: By minimizing energy loss through heat dissipation, busbars optimize the efficiency of electrical systems, leading to significant cost savings over time.

Scalability: In systems that demand flexibility and growth, busbars offer an adaptable solution, allowing for easy modifications and expansions without extensive overhauls.

Reliability: With their robust construction and superior materials, busbars ensure a consistent and dependable flow of electricity, crucial for critical applications where downtime is not an option.

Space Optimization: Busbars facilitate a more compact and organized electrical layout, reducing the spatial footprint and enhancing the aesthetic and functional aspects of electrical installations.

In conclusion, the strategic integration of busbars in electrical systems is not just a technical decision but a testament to foresight and innovation. Their contribution to the seamless, efficient, and reliable distribution of electricity underscores their indispensability in the contemporary electrical landscape. Embrace the prowess of busbars, and empower your electrical systems to perform with unmatched excellence.

FAQs

What is a busbar?

A busbar is a metallic strip or bar used to conduct electricity within a distribution board, switchboard, substation, or other electrical apparatus.

How does busbar protection work?

Busbar protection works by detecting faults and isolating the affected section to prevent further damage and ensure system reliability.

Why is differential protection important?

Differential protection is important because it accurately detects faults by comparing the current entering and leaving a busbar section, providing quick and effective isolation.

Can busbar protection prevent arc flashes?

Yes, busbar protection solutions, such as arc flash protection, can detect and isolate arc flashes quickly, preventing injury and damage.

How often should busbars be inspected?

Busbars should be inspected regularly, typically during scheduled maintenance, to ensure their continued reliability and to detect any potential issues early.

Conclusion – Why do we need them?

Busbars can be used to reduce system costs because they provide a single platform for connecting multiple circuits. Since aluminum and copper are widely used in all electrical systems, busbar systems can be used to reduce costs by minimizing/optimizing the use of copper and aluminum.

Website: https://www.wzjelec.com/

Product: https://wzjelec.com/product

Email: rose@sunjelec.comAuther: Leb