The Ultimate Guide to Insulation Piercing Connector: 5 Tips for Choosing the Best

Have you ever encountered the problem of how to buy Insulation Piercing Connectors (IPC) with good quality and competitive price? To solve this problem, you need to have a good understanding of Insulation Piercing Connectors (IPC connectors) before you can know how to buy cost-effective Insulation Piercing Connectors. Next, I will bring you a comprehensive understanding of Insulation Piercing Connectors from the following aspects and provide 5 tips for buying Insulation Piercing Connectors.

What is an Insulation Piercing Connector (IPC Connector)?

Insulation Piercing Connector (IPC Connector) Mainly consists of a reinforced plastic cover, metal blade, waterproof sealing, silicone grease, high tensile bolts, shear head, and end cap, Insulation Piercing Connector is used to introduce cables in protected low voltage overhead lines (with neutral), transformer downpipes or services.

When cables need to be branched or connected, insert the terminals of the cable branching line into the waterproof terminal cap cover. After determining the branching position of the main line, use a socket wrench to unscrew the torque nut on the fixture. The contact blades pierce the cable insulation during this process. On contact with the conductor, the washer is pressed around the cable puncture location and the silicone grease in the housing spills out. When the torque reaches the set value, the nut torque mechanism is dislodged and the main and branch cables are connected, with waterproof performance and electrical effects reaching the parameters required by the standard.

Can be used in high-rise buildings, civil buildings, street lamp distribution systems, outdoor overhead lines, and other low-voltage power circuits and lighting distribution lines.

Installation Temperature: -10℃-+60

Standard: IEC 61284, EN 50483, IRAM2435, NFC33 020.

Advantages of Insulation Piercing Connectors

- Easy to install, low cost, safe, reliable, and maintenance-free. Piercing connectors can be installed with a suitable socket wrench.

- Cable branches can be made without cutting the main cable or stripping the cable insulation. Piercing connectors are fully insulated and can be operated electrically.

- It is possible to branch at any position of the cable. There is no need to use terminal boxes or junction boxes, and the piercing connector is resistant to deformation, shock, water, corrosion, and aging.

- Cable branching with insulated barbed penetration clips has significant overall benefits and is more cost-effective than previous conventional connection methods.

- Stable electrical performance.

Internal Structure of Insulation Puncture Connector

①Plastic cover: The plastic cover is made of elastic reinforced engineering insulating material weather resistant and UV reinforced thermoplastic PA66, which maintains good elasticity and strength even at high temperatures.

Metal Blade: The metal blade is made of copper tinned, brass tinned, or aluminum alloy. Copper-tinned blades and brass-tinned blades can be used on copper and aluminum conductors. Aluminum blades can be used on aluminum conductors only. Puncture connectors (IPC connectors) are corrosion resistant as demonstrated in corrosion testing. Connector blade teeth will be factory lubricated and sealed to stop water and moisture ingress and corrosion. It ensures optimum contact area on the wire for copper-aluminum transitions.

③WATERPROOF SEAL: The waterproof seal is made of rubber and has strong waterproof performance.

④Cable End Cap: Rubberized cable end cap, a cable end cap is attached to the body of each insulated piercing connector.

⑤ Silicone Grease

⑥ Shear head: The shear head of the insulated piercing connector is designed by precise force calculation and made of zinc alloy, when tightening the optimal piercing force, the shear head will fall off automatically, thus avoiding the disadvantage of poor contact due to excessive force transfer. Damage to wires. Each piercing connector is installed in an optimal state to ensure minimum contact resistance and optimal thermal cycling, overcoming the instability of traditional connection methods.

⑦Bolts: The bolts are made of hot dip galvanized for safe electrically charged installation. The bolts are of the shear head type, which allows control of the effective applied torque during installation and disconnection at a specified torque after establishing a correct connection. It has strong rust and corrosion resistance and a hardness rating of 8.8.

⑧ Washer: Hot-dip galvanized material

Types of Insulation Puncture Connectors (IPC Connectors)

1. According to the voltage classification, insulation piercing connectors can be divided into 1KV, 10KV, and 20KV.

2. Classified according to grounding and ungrounding, Insulation Piercing Connectors can be divided into CRS series and CRSF series.

3. According to the appearance classification, the insulation piercing connector can be divided into PCT13C series 1 bolt, PCT24C series 2 bolts, JBC series 1 bolt and 2 bolts, CRT series, PT series, OEM series.

4. According to the quality classification, it can be divided into common quality and 6KV underwater quality.

5. Classified by bare conductor and insulation, it can be divided into PCT13C series and PCT13CB series.

6. OEM type. Produced according to the customer’s drawing or sample.

Insulation piercing connector performance test

1. Corrosion qualification test

The entire test shall consist of four identical 14-day cycles, with 7 days of exposure in a saltwater environment, an additional 7 days of 8-hour cycles in an SO2 environment, and 16 hours in a laboratory environment.

2. Electrical aging test

3. Underwater high voltage test

Connectors shall be tightened to the minimum torque indicated by the manufacturer. The sample shall be placed in a tank filled with water at a height of 30 cm. After 30 minutes of submersion, the submerged connectors shall be subjected to a 1-minute dielectric test at an industrial frequency of 6 KV. For ±10 mA leakage current setting, no flashover/breakdown should occur within 1 minute at 6KV.

4. Mechanical Test

For checking the electrical continuity, shear head, and mechanical properties of the connectors, appropriate tests are carried out according to the above specifications.

Insulation Piercing Connector Installation

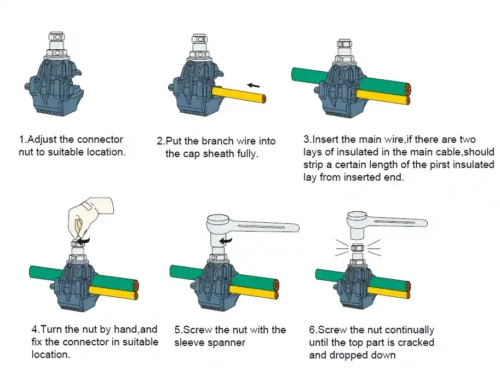

Demonstration of one-bolt insulated piercing connector installation

Required Material:

- One piece of copper tinned single bolt insulated piercing connector

- 1 main conductor 70mm2,1 tap conductor 20mm2

- 1 x socket wrench.

Installation steps:

- 1. Adjust the nut of the insulation piercing connector to the proper position.

- 2. Fully insert the branching conductor into the cable end cap.

- 3. Insert the main conductor. If the main cable has two layers of insulation, strip the first layer of insulation at the insertion end for a certain length.

- 4. Secure the insulation piercing connector in place by hand tightening the nut first.

- 5. Tighten the nut with a socket wrench of the appropriate size.

- 6. Continue tightening the nut until the shear head breaks off and the installation is complete.

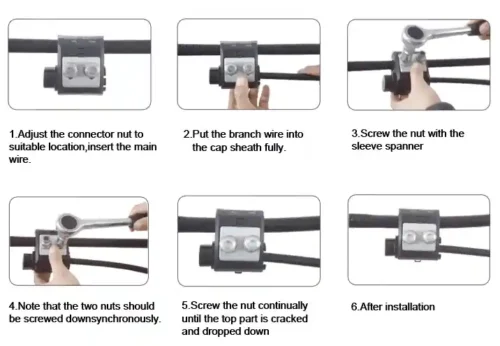

Two-Bolt Insulated Puncture Connector Installation Demonstration

Required Materials:

- 1. One-piece copper tinned 2-bolt insulated piercing connector

- 1 main conductor 70mm2,1 tap conductor 20mm2

- 1 piece of socket wrench.

Installation steps:

- 1. First unscrew the wire clamp and insert the main wire into the main wire slot. Do not twist the main wire with a knife ruler. Note whether the wire diameter range corresponds to this wire clip.

- 2. Insert the branch wire into the branch wire slot.

- 3. Tighten with a socket wrench. Do not use an open-end wrench.

- 4. Note that both nuts should be tightened simultaneously and synchronously.

- 5. When tightened to a certain strength, the constant torque nut breaks.

Installation requirements of piercing connector

1. When stripping the outer sheath of multi-core cable, it is strictly prohibited to cut the core insulation. If there is damage, it should be handled in time according to the general cable insulation repair specifications.

2, the stripping length of the sheath should not be greater than 50 times the diameter of the cable, in the case of convenient installation minimize the stripping length.

3, the outer sheath of the single-core cable should also be stripped, but the stripped length is slightly larger than the width of the threading pliers.

4, the outer sheath stripped, should be exposed at the same time the cable wrapping cut and wrapped with insulating plastic tape at both ends of the mouth so that the filling of the cable wrapping is not exposed.

5, multiple cables installed in parallel in the shaft, the installation position of multiple feedthrough wire clamps should not be in the same plane or elevation, and the distance between the cable outer diameter should be maintained at least 3 times, the installation position should be staggered to reduce the stacking. Volume.

6. Tighten the torque nut of the feedthrough fixture with No.13 and No.17 closed-end wrenches, eyeglass wrenches, and socket wrenches until they come off. Before the torque nut falls off, it is strictly prohibited to use open-end wrenches, movable wrenches, pliers, etc. to tighten the nut. When encountering hard cable insulation, the large nut under the torque nut can be tightened appropriately, subject to not rupturing the wire clamp shell.

Selection of insulation piercing connector (IPC connector) 5 tips

1. before ordering, please confirm the conductor material used in the piercing insulation connector

It is very important to confirm the material of the conductor. If the conductor is an aluminum conductor, you can use an aluminum blade insulation piercing connector (IPC connector). Aluminum blade IPC connectors are cheaper than copper-tinned blades and brass-tinned blades, so you can save money and purchase the right insulation piercing connector.

2. Confirm the conductor range.

It is also important to confirm the conductor range, if the conductor range is not correct, the insulated piercing connector you buy can not be connected, and the loss is very serious.

3. Confirm the blade material.

Confirm the blade material based on the conductor material. For copper conductors, you can choose either a piercing connector with a tinned copper blade or a piercing connector with a tinned brass blade. Puncture connectors with tinned copper blades perform better than those with tinned brass blades and are therefore more expensive than those with tinned brass blades.

4. Ask the manufacturer to provide samples for testing before purchase.

You can ask your favorite manufacturer to provide samples for you to test whether it meets your requirements before purchasing, and then arrange the purchase.

5. Conduct testing before shipment

You can commission SGS or other testing organizations to conduct testing before shipment, which can ensure that the goods you receive meet your requirements.

Frequently Asked Questions (FAQs)

What are insulated piercing connectors used for?

Insulated piercing connectors are used to join electrical conductors by piercing the insulation without stripping it, ensuring a secure and efficient connection.

How do I know if a connector is of good quality?

Look for connectors made from durable materials, with robust construction, and certifications from recognized bodies. Customer reviews and expert recommendations can also provide valuable insights.

Are insulated piercing connectors reusable?

While some IPCs are designed for reuse, most are intended for single use to ensure a secure and reliable connection.

What safety precautions should I take when using these connectors?

Always follow the manufacturer’s instructions, use the appropriate tools, and ensure the connectors are compatible with your electrical system. Avoid over-tightening and follow safety guidelines.

Can I install insulated piercing connectors myself?

Yes, but it’s important to follow the proper installation steps and safety precautions. If you’re unsure, consulting with a professional electrician is recommended.

Conclusion

After reading this article, no matter whether you are a buyer or a salesman, you should have a more comprehensive understanding of piercing connectors and know the key points of buying insulated piercing connectors. If you have any questions, please feel free to contact us. I will tell you everything I know about Insulated Piercing Connectors.

Website: https://www.wzjelec.com/

Email: rose@sunjelec.comAuther: Leb